HPL – What is HPL Laminate?

Production, Properties, Pros & Cons, Areas of Application

When it comes to furnishing and decorating the interior of one's home, most people pay particular attention to the durability, quality and easy maintenance of the materials used, in addition to their design.

In order to satisfy these demands, janEven has chosen a very special material as the tabletop for its exceptionally elegant table series - HPL. HPL laminate is a material that originates from the construction of high-quality architectural facades and therefore both meets very high aesthetic standards and is able to withstand weather conditions such as rain and sunlight. This has made it possible to create a series of tables for the living area that are particularly easy to care for and robust. With its various optional surface colours and particularly striking black wood-fibre core, the material is perfectly suited as a decorative element.

The repurposing of the high-quality HPL material is what makes janEven tables so special.

But surely you would like to know more about HPL: What is HPL laminate? What advantages or disadvantages does the material offer? Is a table with an HPL tabletop suitable for me? We will provide you with the answers to these questions and explain everything you need to know about HPL panels.

HPL - Table of Contents

- What does HPL stand for and how are the panels manufactured?

- Properties of HPL: Advantages and disadvantages of High Pressure Laminate

- High stability

- Easy to clean & hygienic

- Weatherproof

- Fireproof

- Environmentally friendly

- Disadvantages of HPL with poor quality

- Areas of application: Where is HPL wood used?

What Does HPL Stand for and How is the Material Manufactured?

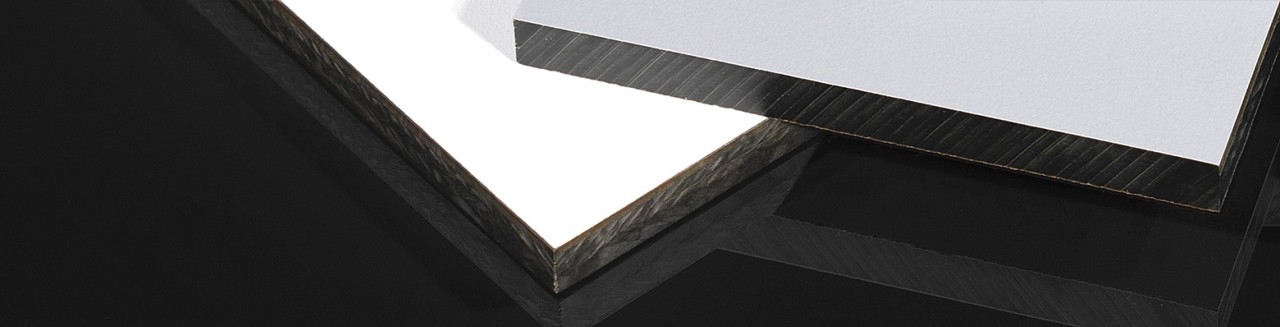

HPL is the acronym for "High Pressure Laminate". However, this is a completely different material compared to flooring laminates, for example, that you should never compare it to. When it comes to HPL, the main priority lies in the naturalness and sustainability of the material. The name HPL already gives an idea of how the panels are produced. Several layers of wood fibres are soaked in melamine resin and then pressed with a cover layer under very high pressure and at intense heat (approx. 120 °C) to form densely laminated sheets.

The resulting HPL laminate board therefore consists of 70 % wood fibres and 30 % resin. Once the resin has fully cured, the material retains its shape and is extremely stable, scratch-resistant as well as heat-resistant, which makes HPL boards particularly durable and high-quality, decorative surfaces. Due to these special properties, HPL has become indispensable in the design of outdoor surfaces and is also becoming increasingly popular in interior decorating.

But the material also offers another special feature: There are virtually no limits to the appearance of the surface finish, as a special decorative paper or a decorative foil with a transparent coating is applied to both sides of the wood fibre core. This not only serves as a top layer, but also makes it possible to produce HPL panels with a wide variety of colours and patterns. This makes HPL an equally practical and highly decorative material.

Properties of HPL: Advantages and Disadvantages of High Pressure Laminate

HPL laminate offers numerous useful properties that make it a robust and easy-to-clean material. If you would like a high-quality product like a table, for example, that you can enjoy for a long time, you will be thrilled with HPL wood. But high-pressure laminate has much more to offer. Therefore, we have compiled all the advantages and disadvantages of HPL for you.

High stability

Thanks to the special manufacturing process and the melamine resin coating, HPL panels have a very strong core with an extremely hard surface. This is why HPL is as rigid and stable as hardly any other material, even though the material thickness is comparatively low. Even blows and impacts cannot harm the material, because it is extremely break- and scratch-resistant - which makes it particularly durable.

Low-maintenance & hygienic

Due to its dirt-repellent properties, HPL does not provide a breeding ground for bacteria and is therefore often used in environments where impeccable hygiene plays an important role (e.g. laboratories or hospitals).

Weatherproof

With their hard core and robust top layer that prevents moisture from penetrating, HPL panels are insensitive to water. Originally, HPL sheets were therefore mainly used for the construction of quality home exteriors, especially for cladding facades, and are still very much in demand as a material for outdoor use. HPL not only withstands changing weather conditions such as rain, high humidity or frost, but is also UV-resistant and thus extremely versatile.

Fireproof

By processing the wood fibres with melamine resin, the synthetic material becomes very heat-resistant and is difficult to ignite. In the event of a fire, HPL does not melt or explode, but remains dimensionally stable for a long time. Similarly, brief contact with cigarette embers does not normally pose a danger to an HPL panel.

Environmentally friendly

Since mainly non-bleached wood fibres are used for the production of HPL boards, the amount of resources required in the form of water is low. This makes HPL a very environmentally friendly product. In addition, the material does not contain any substances of concern, such as halogen or chlorine compounds like those found in PVC, and the surface does not have to be treated with a wood preservative.

Disadvantages of low quality HPL

Despite its numerous beneficial properties, HPL is not completely free of disadvantages. However, these are mainly only found if the board has been processed incorrectly and is of poor quality. Then cracks can appear in the surface, allowing moisture to penetrate the HPL panel and the superimposed layers of wood fibres to swell. The result: the surface casts waves and becomes uneven. If high-pressure laminate is used as a material for outdoors, it should be noted that stains, e.g. from sunscreen or other oils, can be burnt in by the UV radiation. To prevent this, stains should be removed from the HPL panel as soon as possible.

| Pros of HPL | Cons of HPL |

|---|---|

| + Weather resistant to rain, high humidity, frost & UV rays | - In the case of poor quality and inferior workmanship |

| + Extremely stable & scratch-proof | - Risk of irregularities due to cracks in the top layer |

| + Very durable | - Stains can burn in as a result of UV radiation |

| + Easy to clean & hygienic due to dirt-repellent surface | |

| + Flame retardant & fire safe | |

| + Environmentally friendly & resource-saving | |

| + Versatile use | |

| + Various design options |

Areas of Application: Where is HPL Wood Used?

The high-quality laminate is a real all-rounder. HPL boards are suitable for use in very different areas and for various purposes due to their many beneficial properties. Some examples include:

- Façade cladding & patio design: Since HPL combines weather resistance with stability and an elegant look, the material is often used for very high-quality exterior cladding that has to withstand wind and weather. But the laminate is also ideal for patio tiles, privacy screens and balcony cladding.

- Indoor & outdoor furniture: High pressure laminate is often used for garden furniture as well as for interior decor. Especially for tables such as coffee tables or side tables, which need to be robust and at the same time visually appealing, high pressure laminate is the perfect material, making HPL table tops extremely popular. HPL sheets are also often used in the construction of kitchens or office furniture.

- Sanitary areas & wet rooms: Special furnishing objects for sanitary areas are also among the most typical areas of application. Due to its easy maintenance, stability and water resistance, high-pressure laminate is used in sanitary areas, e.g. for room dividers in public toilets or for lockers in swimming pools.

- Arenas: High-pressure laminate is widely used in hockey arenas. Because it can withstand hard impacts without a problem, HPL is used in many places in hockey rinks, which have to withstand the impact of hockey pucks.

From outdoor to indoor use, in public buildings or for private use - its special characteristics make HPL a real all-rounder.